Robotics is a revolutionizing industries worldwide. From healthcare and logistics to manufacturing and construction, these innovations enhance efficiency, reduce costs, and improve safety across various sectors. Concepts like Industry 4.0 have rapid growth due to it. We explore ten cutting-edge robotics innovations shaping the future of automation in 2025.

1. Autonomous Mobile Robots (AMRs) for Last-Mile Delivery

Autonomous Mobile Robots (AMRs) are self-driving robotic systems designed to transport goods in the final delivery stage. These robots navigate streets, sidewalks, and warehouses without human intervention, reducing delivery times and costs. AMRs use AI-powered navigation, LiDAR sensors, GPS, and machine learning to move through urban environments. They avoid obstacles, map real-time routes, and communicate with logistics systems for efficient deliveries. Major logistics and retail companies, including ABB, KUKA AG, Intel, Amazon (Scout), Nuro, and Starship Technologies, have already deployed AMRs for delivery services. These robots are cost-effective, reduce human labor, enhance safety and productivity, and can operate 24/7, making them a practical solution for urban logistics.

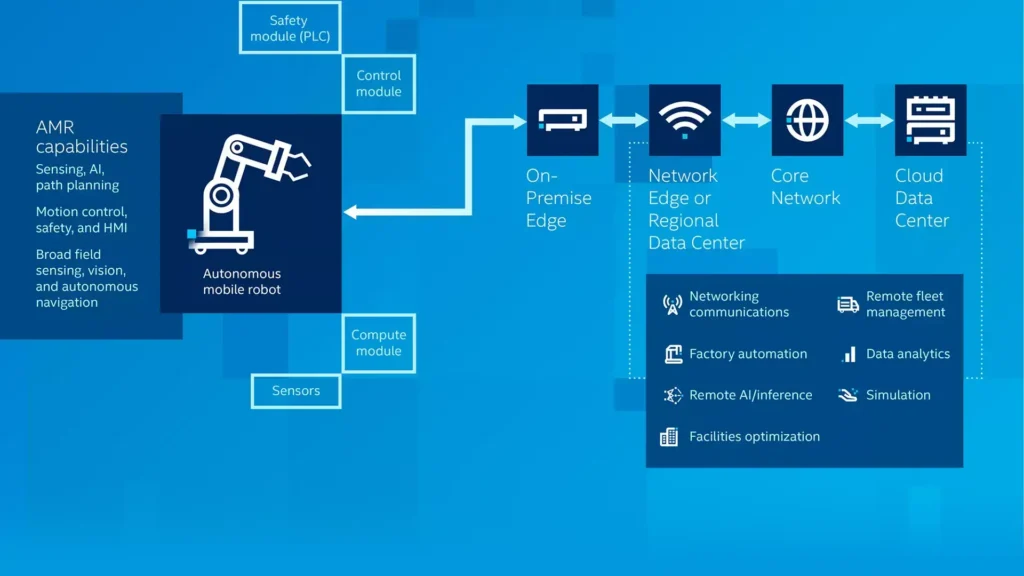

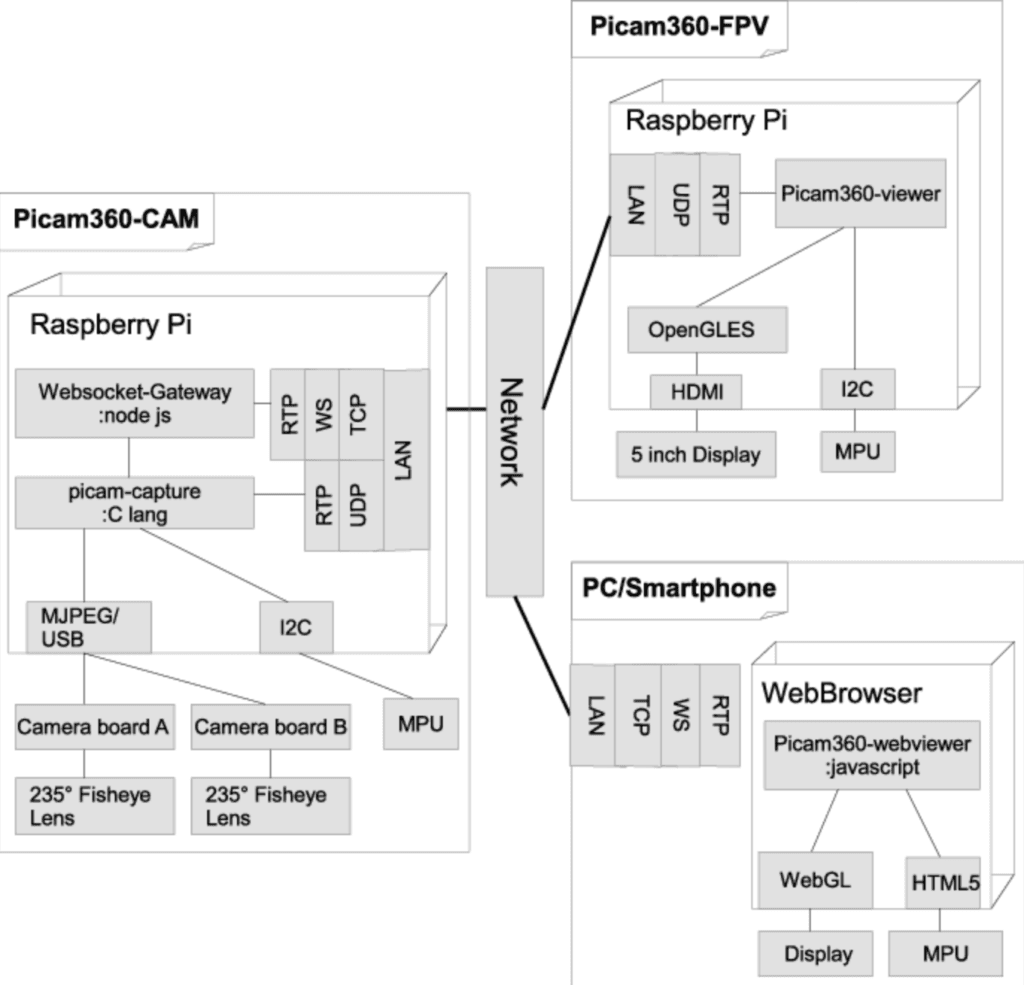

Take a look at intel’s Autonomous Mobile Robot Components and Architecture

Companies like Intel, ABB, Nuro, Amazon Scout, and Starship Technologies are working for the industries to develop AMR.

Applications & Industry Impact

- Retail & E-commerce: Delivers packages and groceries efficiently.

- Healthcare: Used in hospitals for medicine and sample transport.

- Smart Cities: Reducing congestion and carbon footprint in urban areas.

2. Surgical Nanobots

Surgical nanobots are microscopic robots capable of performing precise medical procedures inside the human body. These nanobots revolutionize minimally invasive surgeries and targeted drug delivery. Nanobots enter the body through injections or micro-incisions, navigating the bloodstream or tissues. AI and external magnetic fields control their movements, allowing them to remove blockages, repair tissues, or target cancer cells. While still in research and development, companies like MIT’s Nano Robotics Lab, Medtronic, and California NanoSystems Institute are making significant progress. These nanobots promise less invasive procedures, faster recovery times, and lower healthcare costs.

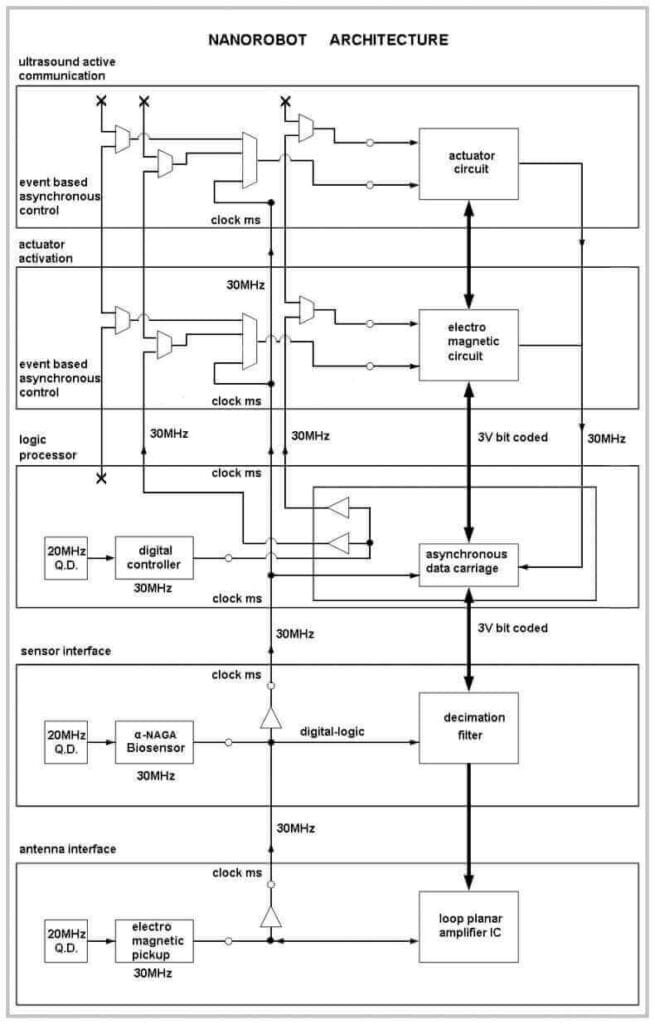

Take a look at nanobot’s Architecture

Companies like Medtronic (Developing nanobot-assisted surgical tools) and MIT Nano Robotics Lab (Creating DNA-based nanorobots.) California NanoSystems Institute (Advancing targeted nanomedicine), Intuitive Surgical (da Vinci Surgical System), Stryker Corporation, Johnson & Johnson, and Siemens Healthcare are creating emerging robots in this field.

Applications & Industry Impact

- Cardiovascular Treatments: Clearing artery blockages.

- Cancer Therapy: Targeted drug delivery to tumors.

- Tissue Repair: Healing damaged organs at the cellular level.

3. Agricultural Swarm Robots

Agricultural swarm robots are small, AI-powered machines that work collectively to improve farming efficiency, crop monitoring, and harvesting. Using computer vision, machine learning, and IoT sensors, these robots analyze soil health, detect pests, and perform seeding and irrigation. Swarm intelligence enables them to coordinate tasks for maximum efficiency. Agricultural robotics is becoming mainstream, with companies like Blue River Technology (acquired by John Deere) and Naïo Technologies leading the way. These robots reduce labor costs, increase yield, and minimize pesticide use, making them highly feasible.

Emerging Companies like swarmfarm, AgJunction, FarimWise, Harvest Automation, Blue River Technology ( Uses AI for precision agriculture), Naïo Technologies (Builds weed-removal robots), and EcoRobotix (Develops autonomous sprayers for smart farming) are working in this area.

Applications & Industry Impact

- Retail & E-commerce: Delivers packages and groceries efficiently.

- Healthcare: Used in hospitals for medicine and sample transport.

- Smart Cities: Reducing congestion and carbon footprint in urban areas.

4. 3D-Printing Construction Robots

3D-printing construction robots use automated additive manufacturing to build homes, offices, and infrastructure layer by layer using cement, plastic, or metal. These robots extrude material following digital blueprints to create walls, floors, and other structures. They significantly reduce waste, time, and human labor in construction projects.

Construction firms like ICON (Built the first 3D-printed neighborhood in the US), Apis Cor (Printed a two-story home in 24 hours, and) COBOD (Supplies 3D-printing robots to the construction sector) already use these robots to build affordable housing, disaster relief shelters, and urban infrastructure. Governments are investing heavily in robotic construction to solve housing crises.

Applications & Industry Impact

- Affordable Housing: Rapid, low-cost home construction.

- Disaster Relief: Emergency shelters after natural disasters.

- Infrastructure: Bridges and commercial buildings.

5. Emotion-Sensitive Service Robots

Emotion-sensitive robots interact with humans using AI, facial recognition, and natural language processing to understand and respond to emotions. These robots analyze facial expressions, voice tone, and body language to adapt their responses, providing personalized experiences in customer service and healthcare.

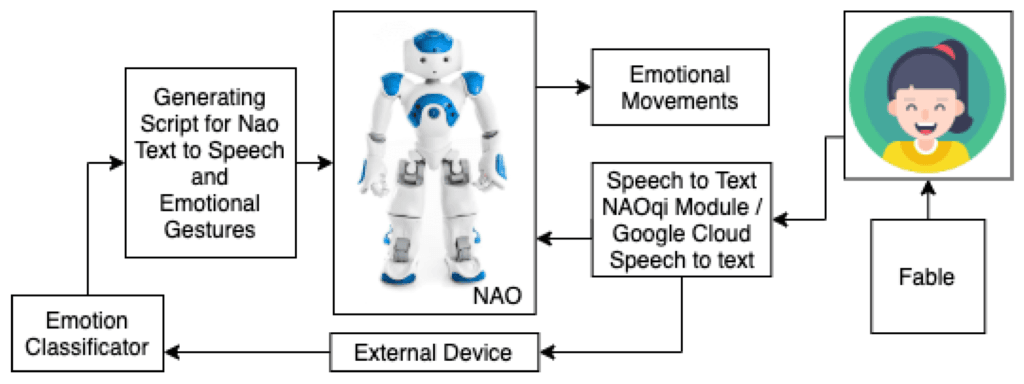

Take a look at Emotion-Sensitive Service Robots Architecture

Retail and hospitality companies, including SoftBank Robotics (Pepper, an interactive robot, was created), Hanson Robotics (Developed Sophia, an AI-powered humanoid), and Furhat Robotics: Builds emotionally intelligent robots), use these robots to enhance customer interactions and mental health therapy.

Applications & Industry Impact

- Retail & E-commerce: Delivers packages and groceries efficiently.

- Healthcare: Used in hospitals for medicine and sample transport.

- Smart Cities: Reducing congestion and carbon footprint in urban areas.

6. Underwater Repair Drones

Underwater repair drones are autonomous or remotely operated robotic systems designed to perform maintenance, inspections, and repairs in deep-sea environments. It reduces human risk in oil rigs, ship hull maintenance, and underwater infrastructure repairs. These drones use AI-powered navigation, sonar imaging, and robotic arms to conduct precision repairs in high-pressure underwater environments. They can be remotely controlled or function autonomously with AI and systematic algorithms.

Take a look at repair drone’s Architecture

Industries like offshore oil & gas, marine engineering, and deep-sea exploration already use underwater drones. Companies like Saab Seaeye (Which provides deep-sea robotic solutions), Ocean Infinity (Which uses autonomous underwater drones for exploration), and ECA Group (Which develops robotic solutions for naval operations)lead this market. These robots reduce operational costs and improve safety compared to human divers.

Applications & Industry Impact

- Oil & Gas Industry: Repairing underwater pipelines and rigs.

- Maritime Industry: Inspecting and cleaning ship hulls.

- Ocean Research: Studying marine ecosystems without disruption.

7. AI-Driven Warehouse “Picker” Robots

AI-driven warehouse picker robots automate inventory picking, sorting, and packing in fulfillment centers, reducing human labor costs and improving efficiency. These robots use computer vision, AI, and machine learning to scan barcodes, recognize items, and transport goods with robotic arms or conveyor belts.

Major e-commerce giants like Amazon Robotics (Uses AI-driven picking systems), Geek+ (Provides smart warehouse automation solutions), and Fetch Robotics (This company specializes in mobile picking robots)are leading the adoption of AI-powered warehouse automation. These robots integrate seamlessly with warehouse management systems, enhancing speed and accuracy.

Applications & Industry Impact

- E-commerce & Retail: Faster order fulfillment.

- Logistics & Supply Chain: Optimized warehouse operations.

- Manufacturing: Automated material handling.

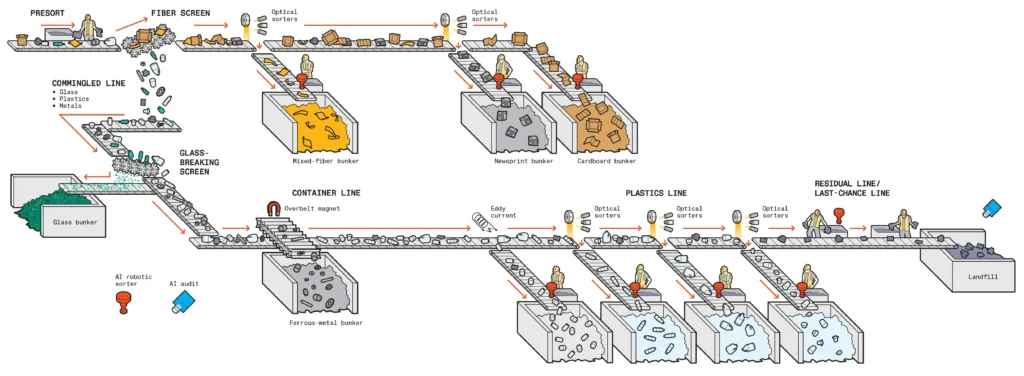

8. Recycling Robots with Computer Vision

Recycling robots use AI and computer vision to identify, sort, and process recyclable materials, improving waste management efficiency. These robots scan materials using image recognition and machine learning, then sort plastic, metal, glass, and paper into separate bins using robotic arms. Governments and recycling companies are rapidly adopting these robots to reduce landfill waste, increase efficiency, and enhance sustainability efforts.

Take a look at intel’s Autonomous Mobile Robot Components and Architecture

Companies like AMP Robotics (Uses AI for smarter recycling), ZenRobotics (Specializes in automated waste sorting), and Waste Robotics (Develops smart recycling robots).are pioneering this sector.

Applications & Industry Impact

- Waste Management: More efficient recycling processes.

- Environmental Sustainability: Reducing landfill overflow.

- Manufacturing: Providing sorted materials for reuse.

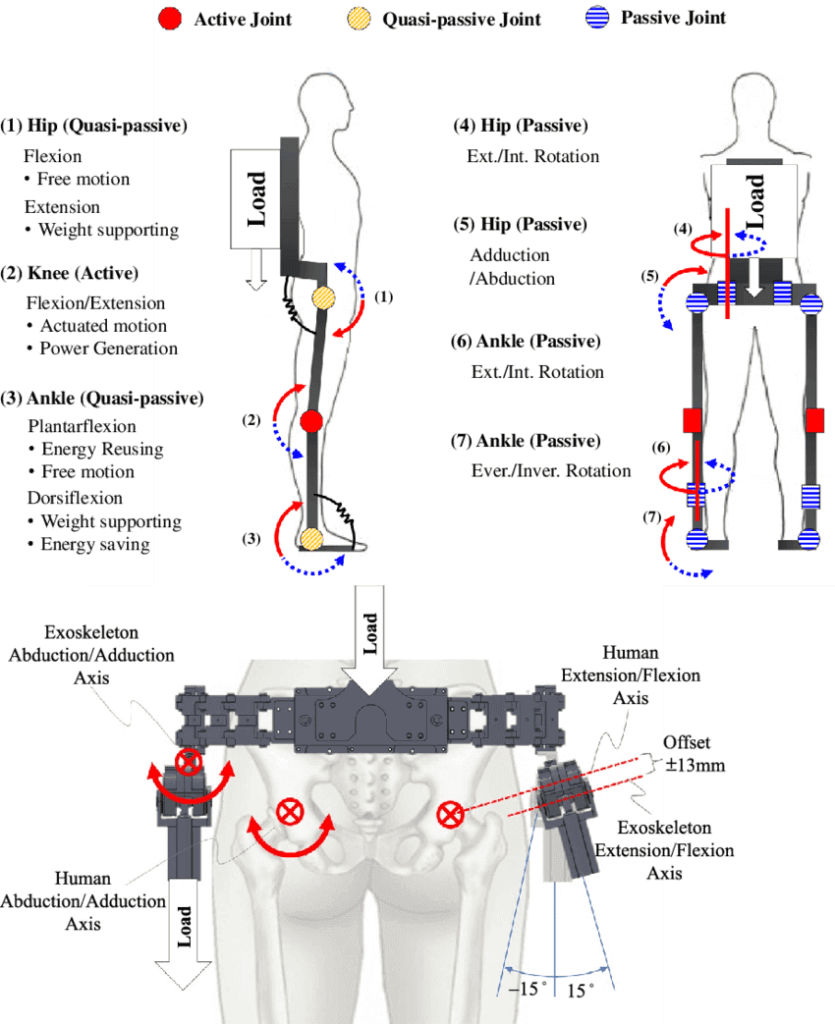

9. Exoskeletons for Industrial Workers

Industrial exoskeletons are wearable robotic suits designed to enhance worker strength, endurance, and safety in physically demanding industries. These suits use hydraulics, electric motors, and AI to support movement, reducing muscle strain and preventing injuries in labor-intensive tasks.

Take a look at intel’s Autonomous Mobile Robot Components and Architecture

Companies like Sarcos Robotics ( Builds industrial exoskeletons), Ekso Bionics (Develops medical and industrial wearable robotics), SuitX: Offers robotic suits for heavy labor industries) AI-powered exoskeletons for industries that include construction, manufacturing, and military applications.

Applications & Industry Impact

- Manufacturing: Reducing fatigue in assembly lines.

- Construction: Assisting workers in heavy lifting.

- Healthcare: Helping disabled individuals regain mobility.

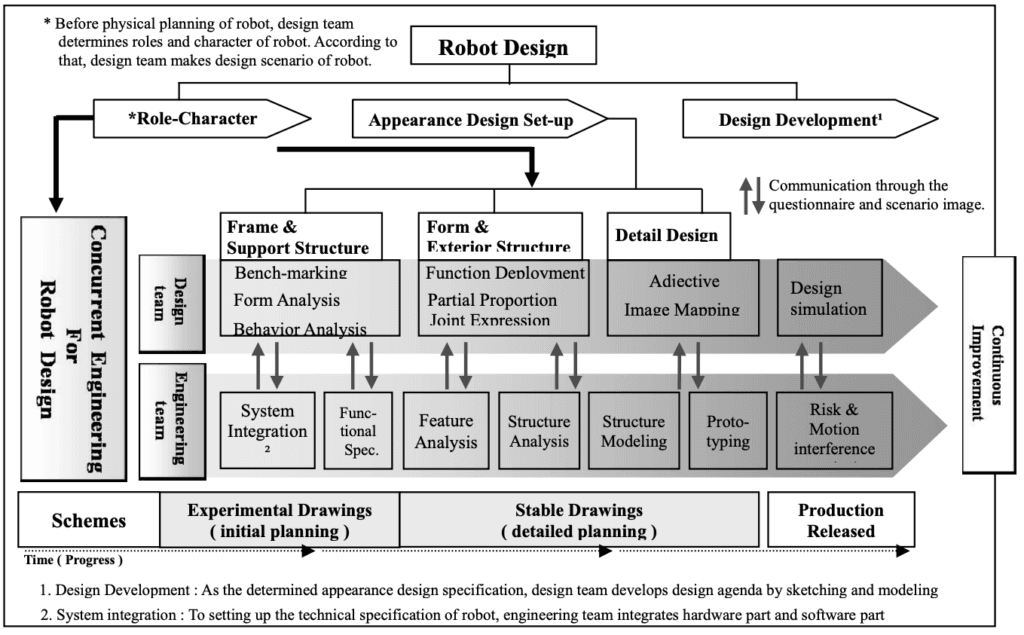

10. Humanoid Robots in Manufacturing

Humanoid robots are AI-powered machines with human-like abilities designed to assist in assembly lines, quality control, and machine operations. These robots use AI, sensors, and dexterous robotic hands to handle complex tasks, including fine assembly work and quality inspections in the automotive, electronics, and aerospace industries. Companies like Tesla (Optimus), Agility Robotics (Digit), and Hanson Robotics are advancing humanoid automation, making these robots cost-effective and scalable for mass production.

Take a look at intel’s Autonomous Mobile Robot Components and Architecture

Companies like Tesla-Optimus (AI-powered humanoid for automation), Agility Robotics-Digit (Advanced humanoid for logistics), and Hanson Robotics (Develops lifelike humanoid robots)are advancing humanoid automation, making these robots cost-effective and scalable for mass production.

Applications & Industry Impact

- Automotive Industry: Assisting in vehicle assembly.

- Electronics Manufacturing: Precision handling of micro-components.

- Healthcare & Research: AI-driven robotic assistants in labs.

Final Thoughts

The robotics industry is evolving rapidly, bringing cutting-edge automation solutions across various sectors. These technologies enhance productivity, safety, and efficiency worldwide, from AI-driven warehouse robots and surgical nanobots to autonomous delivery drones. Businesses adopting robotics and AI will gain a competitive advantage, ensuring faster operations, reduced costs, and enhanced sustainability. The market size is around 3 billion dollars and is rapidly rising. As AI and machine learning advance, expect even smarter, more adaptive robots to reshape industry 4.0 in the coming years.